2025 Case study

Thermal Drone Inspection of Merredin Solar Farm

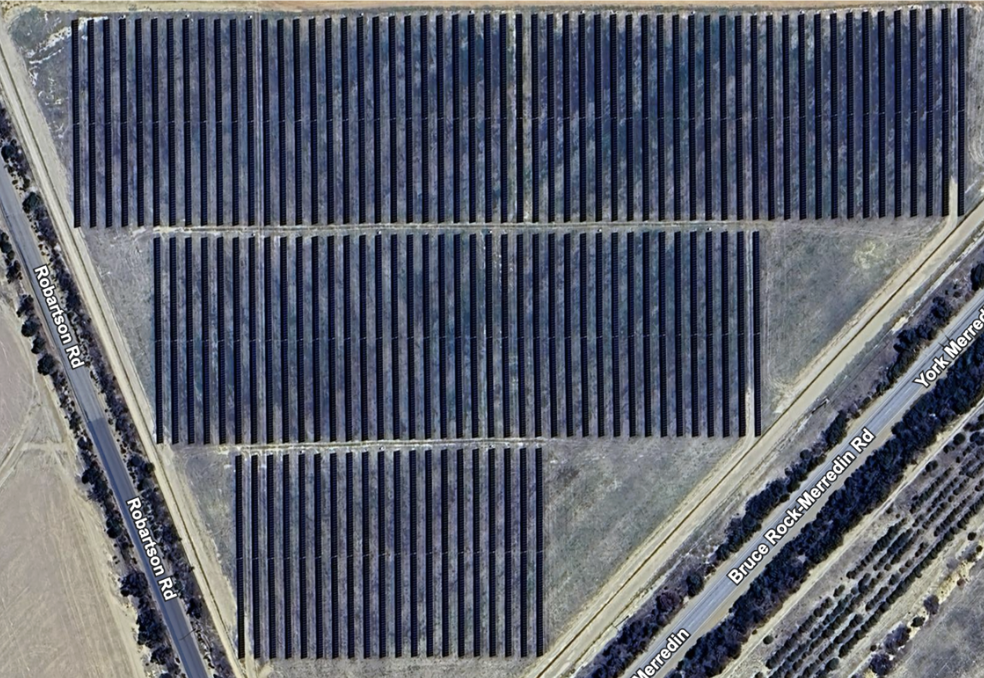

Risen Energy Merredin Solar Farm

On 8 July 2025, Remote Ag Solutions performed a drone-based thermal inspection on a small designated area in Merredin. This inspection was successful in identifying possible fault points in an efficient and timely manner, giving Risen Energy enough time to rectify issues before they became costly and dangerous.

During this inspection, a targeted thermal inspection was commissioned at Risen Energy’s Solar Farm to validate asset health, quantify performance risks, and prioritise maintenance within a designated section. Using high-resolution, drone-mounted thermography under uniform irradiance and stable weather conditions, the survey combined systematic aerial capture with post-flight analysis against baseline thermal profiles to surface fault modes that materially impact yield, safety, and asset longevity.

Introduction

The inspection began with a systematic aerial survey conducted under stable and clear weather conditions. A drone with a high-resolution thermal camera captured real-time data from every panel, ensuring the highest quality of thermal readings.

Methodology

Step 1: Precision Aerial Scan

A drone with a high-resolution thermal camera performed a systematic scan of the solar farm. The flight was conducted in stable, clear weather to ensure data accuracy while capturing real-time thermal readings of every panel

Step 2: Advanced Thermal Analysis

The analysis identified several hidden defects causing energy loss, including 10 instances of bypassed substrings, a single hotspot resulting from a diode failure, widespread potential-induced degradation (PID), and three complete string failures due to open circuits.

Step 3: Identification of Hidden Defects

Convert the defect inventory into clear work orders, including on-site inspection and testing, diode replacement, repair of open-circuit connections, and PID mitigation (grounding/insulation improvements). Add simple follow-through, including cleaning, visual checks, and, where necessary, module replacement. Schedule a verification pass under similar conditions to confirm restored output and to update the baseline set for future comparisons.

Step 4: Development of a Targeted Action Plan

Fault modes identified and Risks

Bypassed Substrings

Parts of a panel (substrings) stopped working together and acted like mini-panels. Thermal images show neat rectangular hot/cool blocks—classic sign of bypassing—so the panel only delivers about two-thirds of its normal power.

Problem 1: Bypassed Substrings (10 instances)

Risks:

Lower energy: around 1/3 power loss per affected panel adds up across the field.

Heat stress: Localised warming speeds up wear on cells and laminates.

Spread across arrays: When many panels in a string are affected, the whole array underperforms.

Higher O&M: More checks and replacements over time.

Single Hotspot from Bypass Diode

(PID + Open Circuit) Fault Analysis

The cell group contained a hot spot, which produced heat in a particular area because the bypass diode had failed. The heat produced in this specific area threatened the module structure while shortening its operational lifespan.

Problem 2: Single Hotspot from Bypass Diode Failure

Risks:

Module damage: Heat can deform or crack the laminate and backsheet.

Shorter lifespan: Accelerated ageing and early warranty headaches.

Safety concerns: Hot-spot runaway presents a genuine risk under conditions of high irradiance.

Unplanned downtime: Panel needs isolating and replacing, cutting production.

Problem 3: Potential Induced Degradation (PID)

The temperature readings between adjacent panels showed patterns that corresponded to the leakage current behaviour resulting from the voltage. The modules that experience PID problems demonstrate both decreased conversion performance and faster deterioration, which shortens production duration and operational lifespan.

Risks:

Daily output loss: Lower conversion efficiency = less energy sold.

Faster deterioration: Affected modules degrade quickly if untreated.

Shorter productive window: It can get “replace/repair” sooner than planned.

Revenue impact: Site-wide losses accumulate over months and seasons.

Problem 4: String Failures – Open Circuits

A connector, fuse, or cable break opens the circuit. Current drops to zero, so the entire string stops producing. Thermally, that string runs cooler than its neighbours because there is no load.

Risks:

Immediate yield drop: Full output from affected strings goes to zero.

Inverter mismatch: Can reduce stability and clip performance elsewhere.

Longer troubleshooting: More time to locate and fix the issue.

Ongoing revenue loss: Each hour that remains unaddressed constitutes energy that cannot be recuperated.

RECOMMENDATIONS

1. Immediate Actions (fault validation & critical repairs)

A scheduled thermal survey under stable sunlight spots hidden faults while they are still small: bypassed substrings, bypass-diode hotspots, early PID patterns, and open-circuit strings. Early findings mean targeted fixes instead of site-wide surprises, less downtime, safer operations, and production that remains steady throughout the season.

2. Remedial Measures (clean, assess, replace when needed)

A clear “fault-to-fix” path turns thermal evidence into restored output: confirm the defect on the ground, repair or replace the exact part, then run a short verification pass to prove recovery. The result is fewer repeat callouts, protection against escalating damage, and a simple audit trail that reassures stakeholders and insurers.

3. Ongoing Monitoring (lightweight thermal cadence)

A light cadence of follow-up thermals in previously affected zones tracks trendlines and catches drift early (especially for PID and recurrent hotspots). Small adjustments with us happen before they become big repairs, keeping portfolios stable, budgets predictable, and warranty conversations straightforward.

Conclusion

The July 2025 inspection of the Merredin solar farm conducted by Remote Ag Solution revealed a range of performance-impacting anomalies, including bypassed substrings, a diode failure hotspot, PID across multiple modules, and open-circuit string faults. Accordingly, these issues illustrate both immediate and long-term threats to the efficiency, reliability, and safety of the array.

By acting swiftly on high-priority findings and adopting a proactive monitoring strategy, Risen Energy can restore lost capacity, prevent further degradation, and extend the operational lifespan of the solar farm. This case highlights the critical role of thermal drone inspections in solar asset management, offering fast, non-invasive detection of hidden faults and providing the insights necessary for data-driven maintenance strategies.